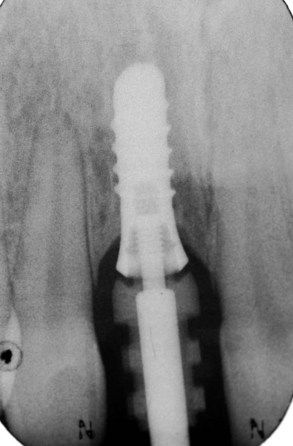

In order to prevent this kind of interference to reseating, the Straumann closed-tray impression abutments are shipped with a polymer cap that prevents impression material from flowing into the screw head. The head of the screw could easily be recorded in the impression and, unless the relationship of the abutment screw and the abutment is exactly duplicated (which is virtually impossible), the abutment may not be able to seat fully back into the impression.

#Straumann impression coping how to#

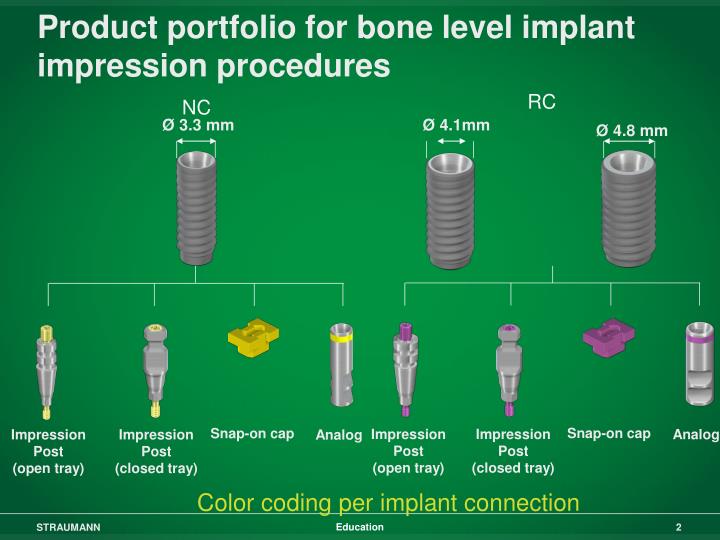

Following this approach allows the clinician to verify that the impression abutment is fully seated and replicates the clinical reality.Īn aspect of the closed-tray impression technique that isn't often discussed is how to best manage the head of the closed-tray impression abutment screw. For this reason, it is a good idea for the clinician to connect the closed-tray impression abutment and the implant analog and then carefully reseat the impression abutment prior to sending the impression to the lab. One factor that frequently results in inaccurate casts using the closed-tray impression technique is related to inaccurate transfer of the impression coping/analog complex into the impression. The closed-tray technique can be very efficient, especially if natural teeth have also been prepared and need to be captured in the same impression. Many clinicians favor closed-tray impression techniques for their individual implant restorations. Individual implant restorations fabricated from an inaccurate cast may require longer insertion appointments, frequently requiring the clinician to alter the proximal or occlusal contacts. An impression for an implant-supported restoration that will connect the implants in the final prosthetic design requires a higher level of accuracy than a design in which the restorations will be fabricated as individual units. The degree to which accuracy is important is based on how the resulting cast will be used. Ultimately, inaccurate impressions may have a negative impact on the definitive outcome if not managed appropriately. Inaccuracy introduced to an implant case at the impression stage has the potential to be propagated, and potentially magnified, as the case progresses. This is especially true with respect to our impressions and the casts fabricated from those impressions.

#Straumann impression coping free#

We currently provide free samples to new customers so you can verify the quality of our abutments yourself.In restorative dentistry, accuracy is important. This is possible because we are confident in our manufacturing process that follows strict manufacturing standards. It makes both financial and logical sense to deal directly with the manufacturer rather than working with wholesalers who are charging you a premium for their custom abutment services.Īll our abutments come with lifetime warranty with a 5-year coverage on the implant system itself. Utilizing this method, we are able to drastically improve our efficiency and lower cost, thus able to pass the savings along to our customers. Compared to majority of other milling centers that are using pre-milled blanks to process their abutments, we employ the latest milling techniques and manufacture the entire abutments "head-to-toe" from titanium rods. has been dedicated to providing the highest quality CAD/CAM custom abutments at the most competitive prices in the market.

0 kommentar(er)

0 kommentar(er)